Home / Reverse

Reverse Vacuums

Reverse two-way vacuums both vacuum and reverse pump out or reverse filter clean. The Spillrite reverse flow certified pneumatic vacuum comes in various models and power settings. The center of the two-ways reversible vacuums is the exceptional opposite jets that permit both vacuuming and converse filter cleaning or pumping out the reverse fluid.

This is an efficient way to collect the liquid and pump it out without any hassle. The entire process is extremely quiet and doesn’t make any heavy noise while the siphoning process takes place in the two-way vacuums.

The powerful ULTRA drum vacuums that fit all drums overall including US55 gallon drums, UK 44 gallon drums and Australian 205-litre drums utilize the novel Spillrite invert jet system. This stream and venturi mix in the reverse vacuums permit the making of the vacuum through the essential jet and afterward with the turn of a ball valve the auxiliary jet is enacted and the drum vacuum turns into an opposite reverse fluid out unit. At the point when the reverse pump valve is initiated and the interior drop pipe is introduced, liquid can be siphoned out of the drum. The reverse filter clean process is also simple, enabling the vacuum to maintain its stability while pumping out.

Read More

During the process, compressed air is pumped into the reverse vacuums to force the liquid out of the vessel. Since there can be no overpressurization because of the venture exhaust, there’s no risk of vacuum failure and other problems. There are different styles of two-way vacuums available that can be utilized for a reverse filter clean and reverse pump-out of the fluid from the vessel. These are explosion-proof vacuums that can be easily used in hazardous settings with ease. The pressure is always kept inside the pump, which is easily regulated to avoid any explosive damages.

The entire process looks like the following:

- Initiate the reverse pump-out valve.

- With the interior drop pipe, set up the strain that will drive the liquid up the drop pipe.

- Through the wand and floor instrument onto the ground or into another drum or vessel.

- Reverse pump-out the liquid with ease.

- Any overabundance development of strain will be constrained out through the exhaust.

- Holding down lashes helps to keep tension inside the drum.

100% SAFE in REVERSE MODE – As there is no mechanical gadget like a spring to keep the tension inside the drum there is no chance that strain can develop inside the drum. All overabundance pressure is delivered by means of the venturi exhaust. Contact Spillrite for your reverse vacuums requirement.

OTHER Reverse MODELS

-

Drum Lid Vacuum 100 cfm ATEX CA Wet Dry Reverse Pump Out

-

Drum Lid Vacuum 100 cfm EX -ATEX – CA-Reverse Pump Out

-

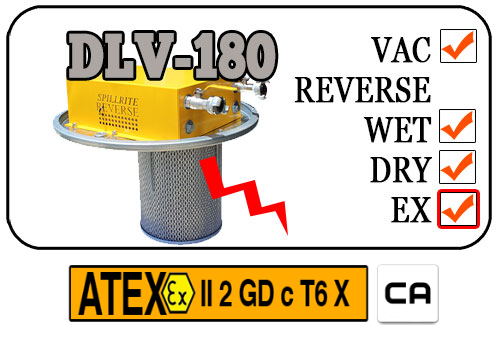

Drum Lid Vacuum 180 cfm Wet Dry EX – ATEX-CA

-

Drum Lid Vacuum 180 cfm wet dry reverse pump out EX – ATEX – CA

-

Drum Lid Vacuum Reverse 100 cfm

-

Drum Lid Vacuum Reverse 180 cfm

-

Drum Lid Vacuum Reverse 180 cfm Filter Clean

-

Drum Lid Vacuum Reverse 50 cfm

-

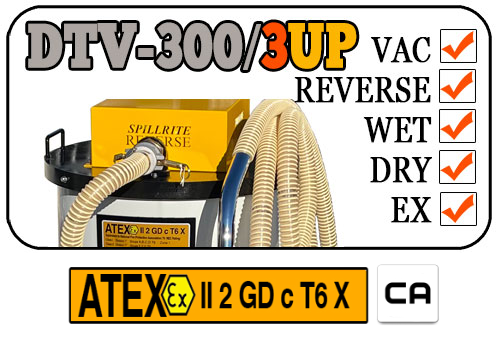

Drum Top Vac 220 cfm Reverse Filter Clean ATEX CA

-

Drum Top Vac 300 cfm Ultra Stainless Reverse Filter Clean ATEX CA

-

Drum Top Vac 300 Ultra Reverse Filter Clean ATEX CA

-

Drum Top Vacuum 110 cfm Reverse Filter Clean

-

Drum Top Vacuum 220 cfm High Power 3 – Reverse Filter Clean

-

Drum Top Vacuum Cyclone Combo 110 cfm ATEX – CA

-

Drum Top Vacuum Cyclone Combo 220 cfm HP3 ATEX CA